-

bri.industries@yahoo.com -

08048774157 - Send SMS

- Send Email

- GST No. 36AEZPK4957P1Z8

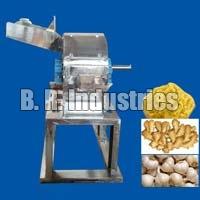

Cone Pulverizer

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Pulverizers |

| Weight | 100-1000kg |

| Voltage | 220V |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Cone pulverizer is a machine that is widely used to grind items such as turmeric, besan, dry ginger, coconut shell, chemicals, aquafeed, etc. We are a cone pulverizer manufacturer in Telangana offering high-quality machines. Cone pulverizers manufactured by us are sturdy and hence, they are also noise and vibration-free. The machines have a feeding rate that can be easily controlled. Our machines are available in stainless steel, mild steel, and stainless steel lining. They function on frictionless grinding and hence, are very efficient in grinding the materials into the finest quality.

As a cone pulverizer exporter Telangana, we export machines to various parts of the world at the most reasonable and competitive price. Our experts ensure that all our products are tested for their quality before being exported. We are also the most trusted cone pulverizer supplier in India and are known for timely delivery of products across the country and abroad.

Looking for a cone pulverizer exporter from Telangana for your specific needs? Then you can contact us. We cater to customised needs of our customers across the globe. We also ensure that the orders are delivered on time to maintain a good customer relationship. So, contact us to get the best quotes for your bulk orders.

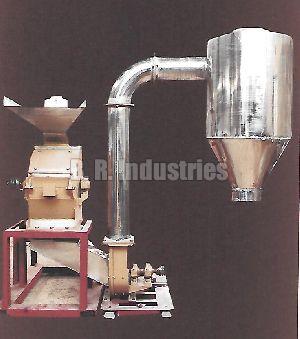

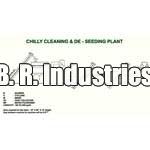

CHIILI POWDER MACHINE

|

Specification of Micro Pulveriser(Single Machine for Grinding all kinds of Spices) Micro Pulveriser is provided with Cyclone, Blower, foundation channel frame and Dust-collector. Works on the Principle of cutting & crushing thereby retains original valuable product qualities. Product fineness is controlled by change of perforated sieves.It is a Hammer Mill. Suitable for Chilies, Coriander, Black Pepper, Tea, Sugar, Husk, Roots, Neem seed , Turmeric etc. Available in wide range of capacities in Mild Steel, Stainless Steel & Stainless Steel lining. (Moisture Content should be 10%) |

|

|

Specification of Chilly Grinding Plants with chilli cleaning system.(capacity 900-1000 Kgs per Hour) With S.S.Lining inside the body(after passing through cleaning system through whole process the Contact parts to chilli will be in S.S.(304 Grade).

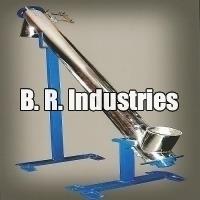

Feeding whole chilli manually through Belt Conveyor, Chilli Cleaning Machine 1 No. removes Dust,nails, stones and hard particles from Chiili, three outlets in chilli cleaner, through two outlets dust particles will be removed and the cleaned whole chilli fall down in the third outlet, Suction Blower sucks the cleaned chilli from and throws the chilli first Stage Grinding chilli passes through 3.5 mm hole Screen, through screw conveyor -> second stage Grinding passes through 2 mm -> 1.25 mm hole Screen, And then -> third stage Grinding passes through 1.25 mm here you get the final product (fine powder) final product through Screw Conveyor the final product fall in Mixeris attached to the Plant final product store into the mixer (oil mixing tap is provided) and cooling of fine powder also takes place before bagging in the Mixer. in which tap is provided for 2% oil Mixing In mixer you can Blend 2-3 different qualities It is an continuous process of Grinding and only 3-4 mens required while running the plant. Plant available in capacities :(Moisture Content should be 10%) |

|